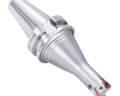

Fullcut Mill FCR Type

Square-Shoulder, Helical, and Ramping Milling Cutter

Fullcut Mill FCR Type is an indexable insert end mill offering supreme cutting performance for your most demanding milling applications. FCR offers lower cutting resistance than any other competitors. A rigid integral body is optimal for all machining centers. The positive high rake sharp cutting edge for both radial and axial directions achieves smooth and quiet end milling.

Designed for shoulder and slot milling, ramping, helical milling, and plunge milling.

Indexable Milling

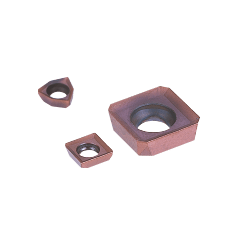

The Fullcut Mill FCR Type is a versatile tool for indexable milling, thanks to its unique inserts designed for ramping. This allows for multi-functional cutting, including helical milling, peck-milling, grooving, and shoulder milling. FCR Type has been tested and proven to have five times greater DOC capability and lower cutting resistance than three competitors’ tools, making it a top choice for your milling needs. The sharp cutting edges of the unique indexable insert retain high strength and toughness, allowing for smooth and quiet endmilling in all materials.

- High rake angle and ground cutting edges sharply reduce cutting resistance

- Strong cutting edge reduces edge chipping

- Lower cutting resistance than any other competitors

- Achieves 5 times greater DOC than other high rake cutters

- Higher rigidity with integral body and dual contact system