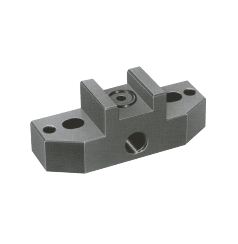

Coolant Inducers

Coolant Inducers

Coolant Induced Shanks

Coolant Induced Shanks

Hi-Jet Holder coolant inducers introduce coolant capabilities to machine tools without coolant-through spindles. Hi-Jet Holders minimize overheating and distortion of workpieces and allow coolant-through cutting tools to provide faster metal removal rates by flushing chips out of the holes. With reduced heat generation, tool life is greatly extended.

Features & Benefits

- Introduces coolant capability

- Allows operations at faster speeds and feeds

- Non-contact seal design eliminates wear damage to the body

- Automatic Tool Change w/ stop block

- The sturdy one-piece design of shank and tool holder

Product Documentation