CNC Boring Tools

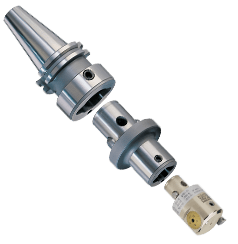

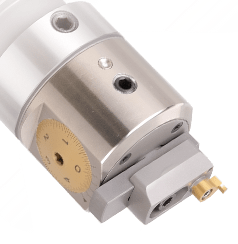

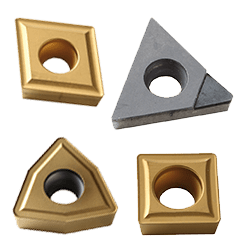

The precision and ruggedness of BIG KAISER modular CNC boring tools deliver measurable performance advantages—significantly reducing costs and cycle times. The modular CK system is the best solution for drilling, rough boring, finish boring, milling and tapping. Modular boring tools provide flexibility to assemble the perfect setup for almost any application.

Through systematic development combined with countless practical tests, the well-known CKB modular system can be easily upgraded to cope with the requirements of today's high-performance tools.

Have A Question?

Ask Our Tooling Experts!

We assist with product, account and procedure questions. We design tool set-ups, schedule service calls and help our customers receive the maximum efficiency from our tooling.