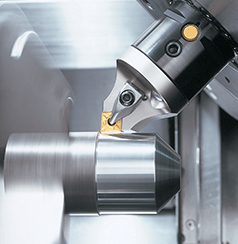

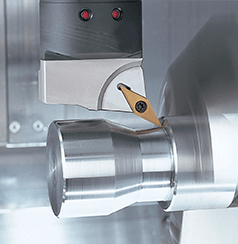

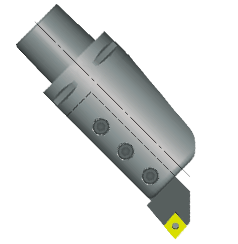

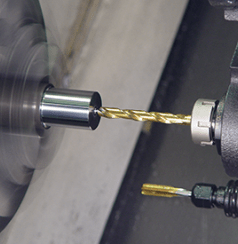

Multi-Axis Turning Tools

The very first modular tooling system developed for Mill/Turn Centers (MTC’s) and 5-axis milling machines with C-axis turning capability. Modular Turning Tools for most common spindle interfaces offers optimal tool length, large selection of insert types, approach angles, and a variety of standard boring bar and square shank adapters.

Have A Question?

Ask Our Tooling Experts!

We assist with product, account and procedure questions. We design tool set-ups, schedule service calls and help our customers receive the maximum efficiency from our tooling.