CNC Tool Holders

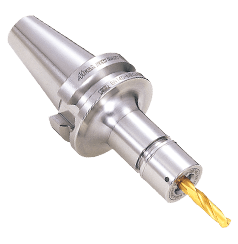

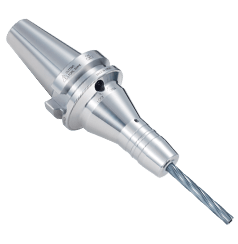

CNC tool holders are the interface between the machine spindle and the cutting tool. BIG DAISHOWA offers a wide variety of shanks common to the market, including both BIG-PLUS and standard versions of DV(DIN69871), BT(JIS B6339), and CAT(ASME B5.50) steep tapers as well as HSK (ISO12164) hollow shank tapers and BIG CAPTO (ISO26623-1) polygon taper shanks.

We offer a wide range of tool holder technologies for the highest possible performance in specific types of applications. Including collet chucks, mechanical milling chucks, hydraulic chucks, shrink fit holders, side lock end mill holders, shell mill adapters, and tapping chucks.

Learn More

Have A Question?

Ask Our Tooling Experts!

We assist with product, account and procedure questions. We design tool set-ups, schedule service calls and help our customers receive the maximum efficiency from our tooling.