AIR POWER SPINDLE

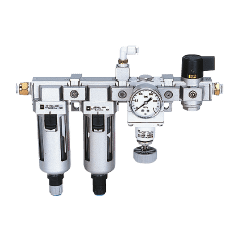

High-speed micro-machining can be achieved on a standard machining center, eliminating the need for an expensive high-speed machine, thanks to the innovative air power spindle technology.

Dynamic Runout Accuracy

Most issues related to micro-machining stem from poor dynamic runout of a machine spindle. Our specialized system detects spindle movement during high-speed rotation, ensuring the best dynamic runout accuracy with our air power spindle.

Minimized Spindle Expansion

Our air turbine drive effectively prevents thermal expansion of the spindle, crucial for maintaining high accuracy in micro-machining processes.

Automatic Tool Change

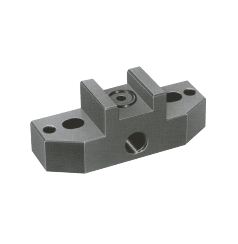

We offer an ATC type that optimizes productivity through automated, unmanned operations by supplying air via a stop block, powered by our advanced air power spindle technology.

- Outstanding dynamic runout accuracy

- Minimized Z-axis thermal displacement

- Extended tool life

- Superior surface finish

- Ultra-high-speed and precision

- Automatic Tool Change possible for Center and Side Through Types

- Ultra-low vibration

- Low noise design (within 65 dB)