Dyna Test

Dyna Test

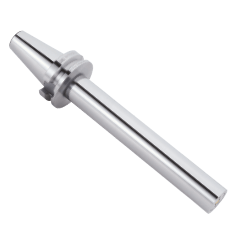

Dyna Test Overview

Dyna Test Overview

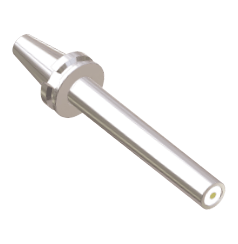

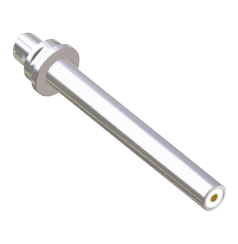

Dyna Test is a precision test bar for static accuracy. It is developed by BIG DAISHOWA using advanced technology and strict quality control. Using a Dyna Test bar for inspection on a regular basis helps to identify potential problems with spindles and bearings to help you reduce downtime and costly repairs. The precision test bar helps you test the runout of the spindle, and you can also check the parallelism of z-axis movement.

Features & Benefits

- Helps reduce downtime and costly repairs

- Identifies potential problems with spindles and bearings

- Comes with an aluminum case to protect and store the test bar

Product Documentation