Cleaners

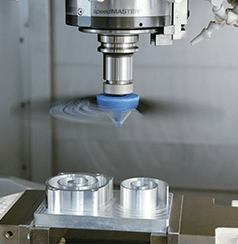

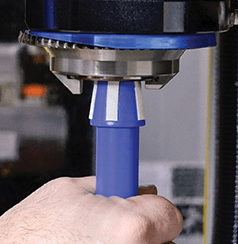

Considering we deal in some of the smallest parts and pieces in the machining world, we fully understand that your results will be only as strong as your weakest link. A single chip landing in the wrong spot or a small buildup of particulate can throw off a whole operation or damage your tooling and machine mechanics.

Fortunately, there are affordable accessories that help prevent some of these expensive doomsday scenarios. Our cleaners make it easy to get your spindle and tooling in the best condition to perform exactly as desired over and over. After all, your machine may have been installed last week, but if these connections aren’t pure, achieving those tight tolerances and shimmering finishes won’t happen.

Have A Question?

Ask Our Tooling Experts!

We assist with product, account and procedure questions. We design tool set-ups, schedule service calls and help our customers receive the maximum efficiency from our tooling.